- Home

- Impact Report

| Use to annual impact report 2024 |

|---|

Annual Impact Report 2024 |

| Use to view more |

|---|

Salsa Jeans' business strategy is based on the principle of transparency, assuring environmental impact is minimised in all the decisions we make.To this end, we created “Become”, our social responsibility and environmental programme that reflects who we are and our commitment to people and to the planet. This is the responsibility we take on, to do what we do best, respecting the ecosystem we are all part of. We work every day towards the “Principle of 100%”, which means we approach each issue with the aim of bringing about a 100% change or improvement in our production chain, a certain family of products, some specific process... honestly and transparently. Our goal and our actions have always been influenced by progress. We look at this second impact report as a way of measuring the small victories won and understanding the road we still have to travel. After three years of execution with encouraging results, we feel that, in order to adapt to the current challenges and to speed up the pace of implementation, we should start organising our initiatives into six critical action areas – Water and Effluent; Energy; Packaging and Waste; Circularity and Biodiversity; Supply Chain Traceability; People – and it is through these that we are presenting the results achieved here (and the new commitments defined) in 2024. |

| Use to view more |

|---|

| Use to view more |

|---|

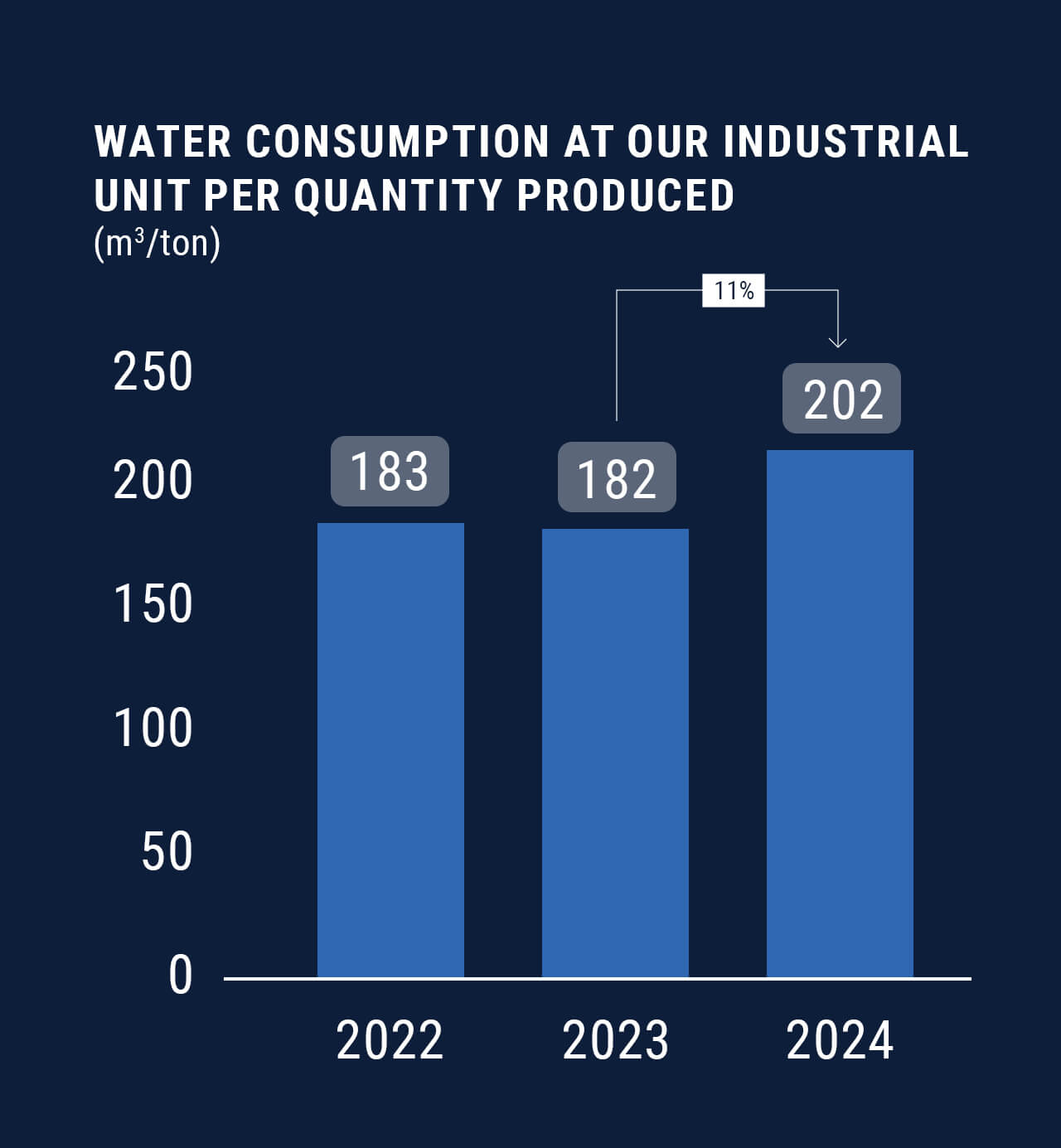

Water and EffluentWater is a scarce resource, and should therefore be used efficiently, minimising the environmental impact and conserving local ecosystems. To this end, we are committed to introducing measures to reduce water consumption and ensure appropriate treatment and discharge of effluent in all our operations and across our supply chain. In 2021, we introduced Betterwash®, a certified washing process aimed at reducing water consumption through more advanced techniques, such as ozone, laser and e-flow, instead of more traditional techniques. According to a study carried out with the support of Control Union, we concluded that we reduced average water consumption per item produced by 42% between 2013 and 2021. This reduction came as a result of the techniques adopted at the time Betterwash® was implemented, the investment made in factory machinery, the introduction of optimisation processes and the relationship we have with our suppliers. After identifying and consolidating these techniques and processes in our industrial unit, we decided in 2024 to move on to the second phase of this project and introduce a Betterwash® policy, a broad technical definition of the best practices we follow in water consumption and effluent production. This policy should be followed by all our suppliers, so that they too will be able to improve their water management. By working together like this, we help our suppliers to implement more responsible solutions, aligning them with our internal levels of environmental responsibility, and promoting positive change in the textile industry. As an integral part of Betterwash, water consumption should be monitored at all our facilities. |

| Use to view more |

|---|

|

| Use to view more |

|---|

Despite the investment made in modernising our industrial processes and capacity in 2024, total water consumption at our facilities increased by 29%, with the most significant increase taking place in industrial processes: between 2023 and 2024, water consumption by quantity produced increased by 11%. |

| Use to view more |

|---|

We are aware that the management of liquid effluent in the textile industry is crucial for minimising impacts, given that these processes generate large volumes of water containing chemical products such as dyes, pigments and solvents. After physical separation of the components, the wastewater is sent to the Rio Ave Wastewater Treatment Plant (TRATAVE) for final treatment of the effluent, and then returned to natural watercourses, respecting the parameters defined by law. In 2024, despite the higher water consumption already mentioned, the levels of effluent sent increased by only 3%. |

| Use to view more |

|---|

|

| Use to view more |

|---|

| Use to view more |

|---|

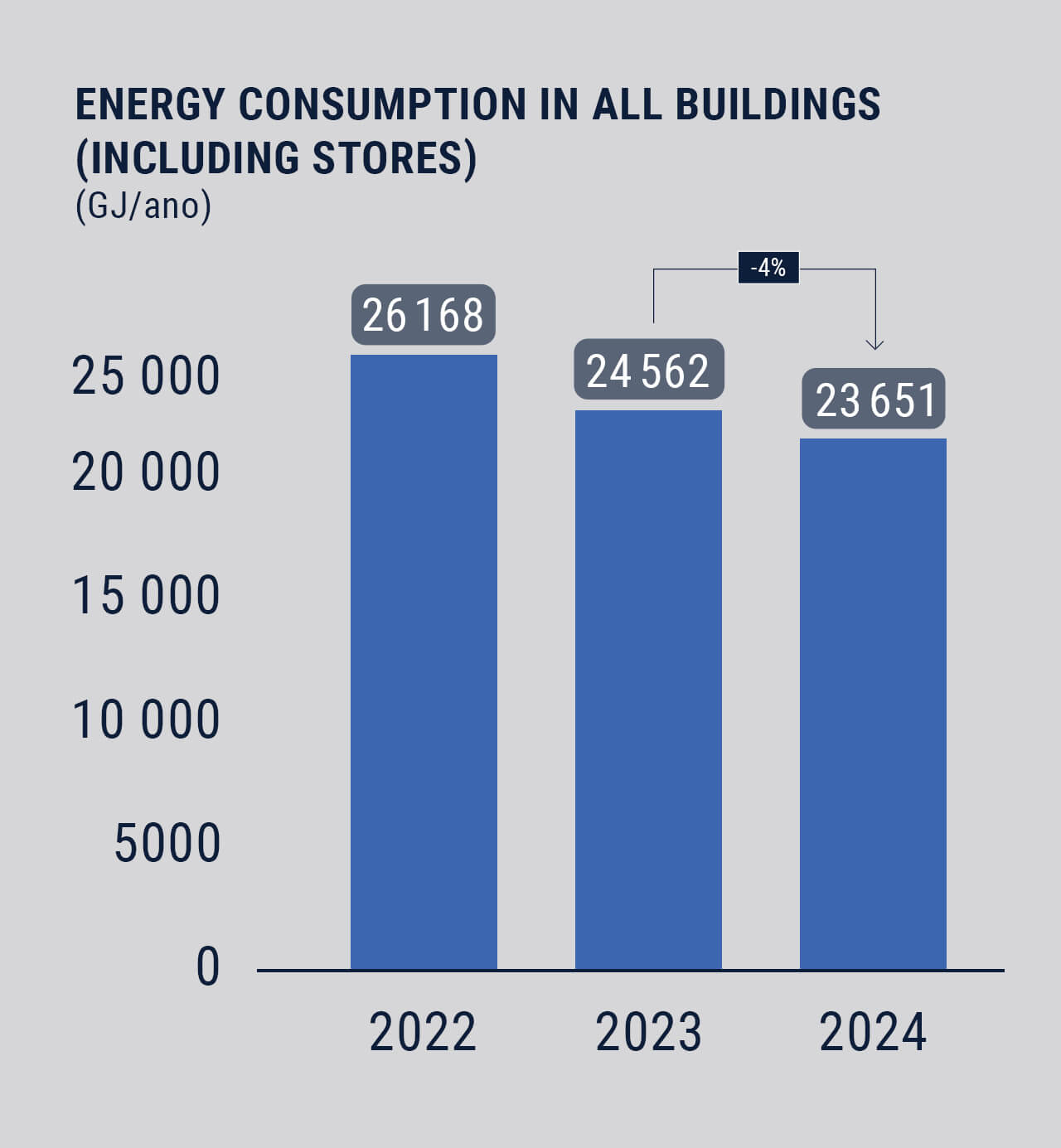

EnergyWe are committed to energy management through calculating and monitoring greenhouse gas emissions in all operations, in accordance with the Greenhouse Gas Protocol, bringing the carbon neutrality goal forward from 2050 to 2040. |

| Use to view more |

|---|

|

| Use to view more |

|---|

Between 2023 and 2024, and by introducing new practices and increasing the efficiency of the equipment installed, energy consumption at our facilities (which include our central offices, a warehouse and our industrial unit and own shops) fell by 4%, with energy consumption per m2 in our shops decreasing by 11%. |

| Use to view more |

|---|

In 2024, 41% of all the energy used in the Salsa Jeans headquarters (offices, warehouse and industrial unit) came from renewable sources, with 15% of the total energy used being generated by the production units through solar panels installed in our offices and industrial unit. |

| Use to view more |

|---|

|

| Use to view more |

|---|

|

| Use to view more |

|---|

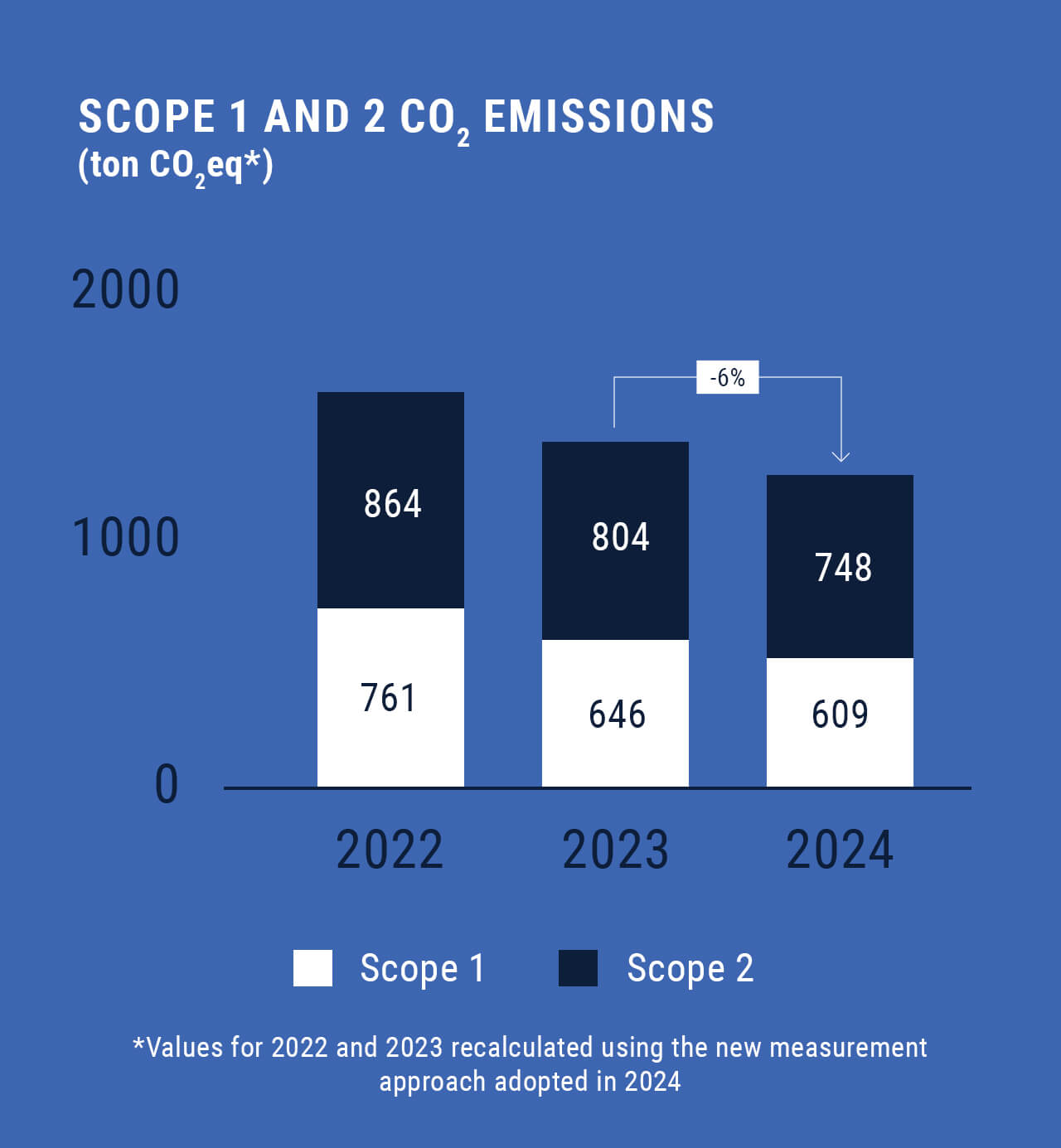

Between 2023 and 2024, we recorded a 6% reduction in Scope 1 and 2 CO2 emissions. Scope 1 emissions fell by 6%, corresponding to direct emissions from operations belonging to or controlled by the company (e.g. fleet and fluorinated gas emissions from air conditioning systems). Fleet fuel consumption decreased by 12% due to the increase in the electric/hybrid fleet and the reduction in the fossil fuel fleet, as well as the installation of four more electric charging stations at our facilities (offices). In addition, we found that there was a 7% reduction in Scope 2 emissions, which are associated with indirect emissions from energy consumption (particularly electricity) in the company's activities. |

| Use to view more |

|---|

| Use to view more |

|---|

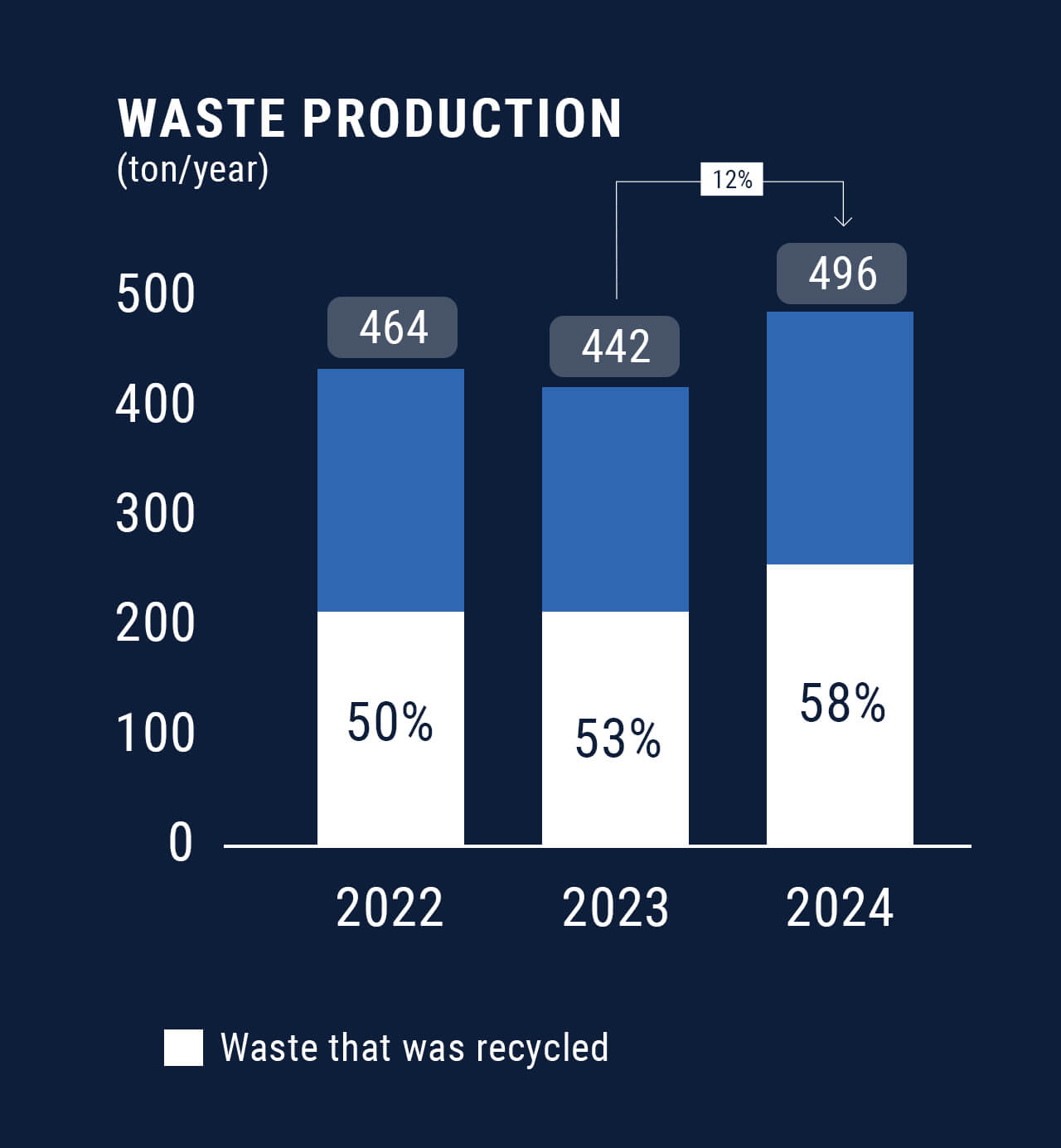

Packaging and Waste |

| Use to view more |

|---|

Packaging |

| Use to view more |

|---|

|

| Use to view more |

|---|

|

| Use to view more |

|---|

Waste |

| Use to view more |

|---|

| Use to view more |

|---|

Circularity and Biodiversity |

| Use to view more |

|---|

INFINITY |

| Use to items handled since the launch of infinity (un.) 5327 items repaired 1589 items collected |

|---|

Items handled since the launch of Infinity  5327 ITEMS REPAIRED  1589 ITEMS COLLECTED |

| Use to view more |

|---|

|

| Use to view more |

|---|

Circularity |

| Use to view more |

|---|

| Use to view more |

|---|

Supply Chain Traceability |

| Use to view more |

|---|

Our partners are fundamental to our strategy. We work behind the scenes to bring customers a product that’s unique, exclusive and special. |

| Use to view more |

|---|

|

| Use to view more |

|---|

|

| Use to view more |

|---|

We work towards having a balanced production chain in terms of the mix of origins, complementing our network of local suppliers (which, apart from Portugal, includes Spain, Morocco, Tunisia and Turkey), with a smaller number of suppliers from further afield (particularly Asia). We have always fostered a relationship of continuity with all of them, assuring the support and development of the communities they are part of. In 2024, 50% of our suppliers were from neighbouring countries. |

| Use to view more |

|---|

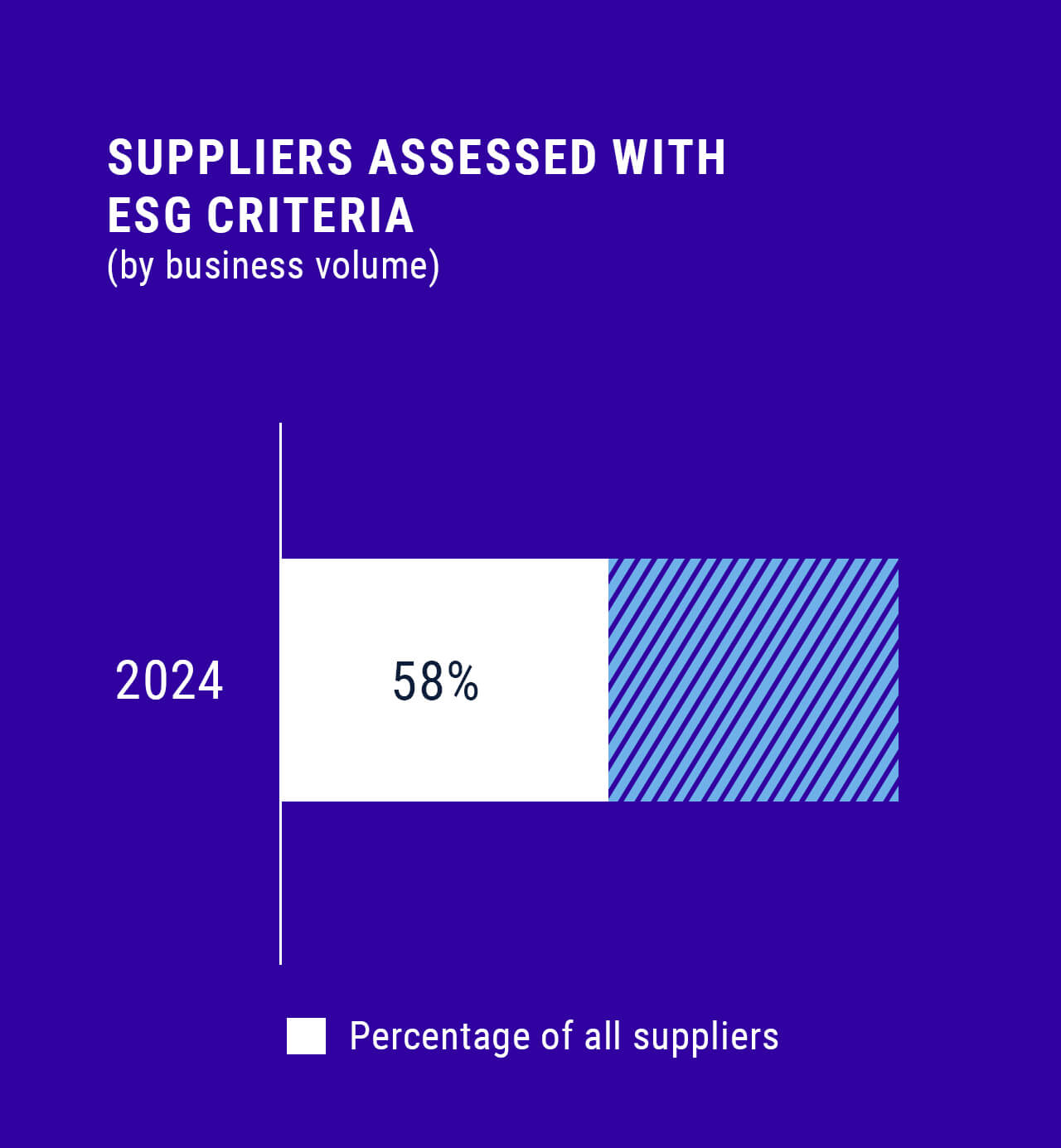

We want to ensure that 100% of our suppliers comply with ESG (Environmental, Social and Governance) criteria by 2026. In order to achieve this goal, all suppliers are initially assessed through their environmental and social certification, and then audited externally. In 2024, 58% of our suppliers received a positive assessment according to ESG criteria. |

| Use to view more |

|---|

|

| Use to view more |

|---|

| Use to view more |

|---|

PeopleAt Salsa Jeans, we are committed to conscientious business practices that respect the rights of all. This means that, from our employees to our partners, our goal is to assure the best conditions and relationships so that everybody can feel motivated, safe and, above all, passionate about the work they do every day. |

| Use to view more |

|---|

|

| Use to view more |

|---|

Equity and Diversity |

| Use to view more |

|---|

Reborn |

| Use to view more |

|---|

|

| Use to 49h average training hours per employee +50 employees with academic progression |

|---|

49haverage training hours per employee  +50employees with academic progression |

| Use to view more |

|---|

Training |

| Use to view more |

|---|